Innovation is the key driver of P&WC’s growth. That is why we focus on research and development in many aspects of our business. The importance of global networking and collaboration between our production units and end-users of our products is a significant reason for our successful innovation efforts.

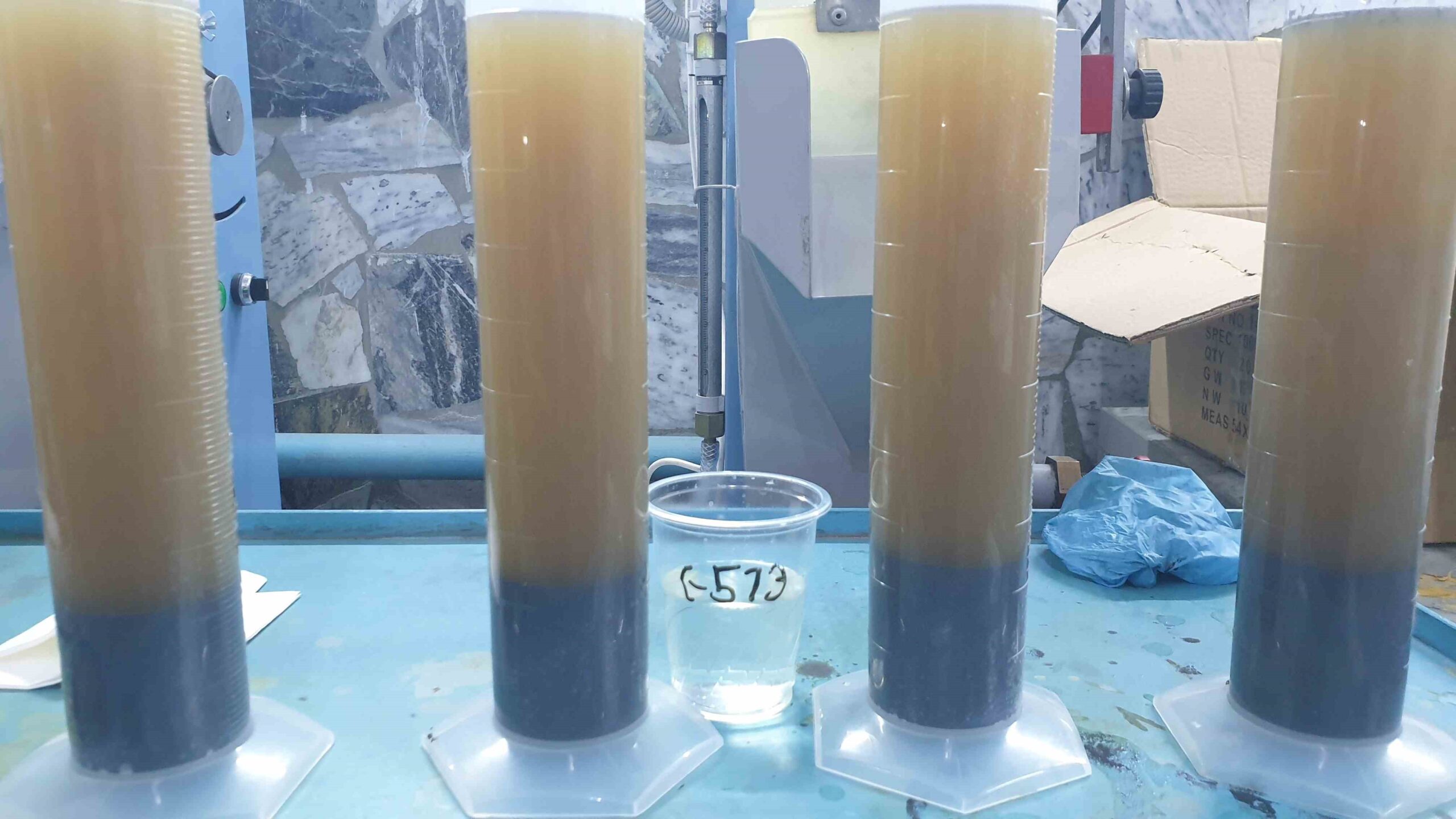

During the period from November 28 to November 30, 2023, in the research laboratory of the Metallurgical Plant No. 3 of the Navoi Metallurgical Plant, with representatives of the Kemira and together with workers of the plant laboratory conducted experiments to find the most effective reagent or combination of reagents for sedimentation and clarification of pulp in a countercurrent lag scheme.

The use of flocculants of the HYFLOC CP series increases the sedimentation rate almost twice as compared to other flocculants with the same reagent dosage – 23 g/t and allows you to obtain a very dense sediment.

The best result in drain transparency was shown by the flocculant HYFLOC NP300 with an indicator of 144 NTU

The sedimentation speed of all tested flocculants is in the same range of 9-10 m/hour, the sediment density is 240 – 250 ml, which is quite sufficient.

The use of coagulants of various brands improves the transparency of the drain.

The use of a coagulant before feeding the flocculant improved the clarity of the discharge for HYFLOC NP300 from 144 NTU to 117 NTU, which was the best result in the entire series of tests